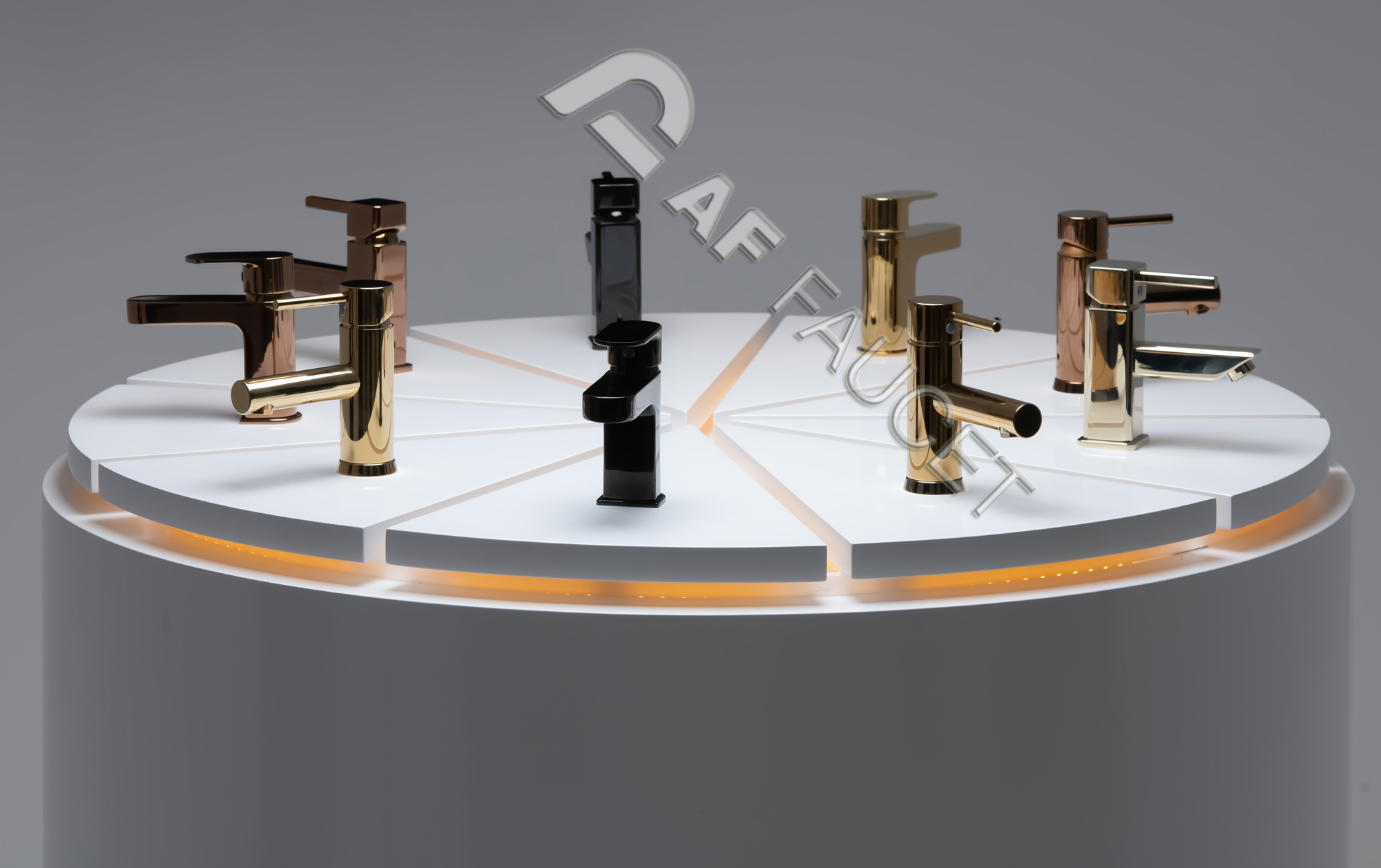

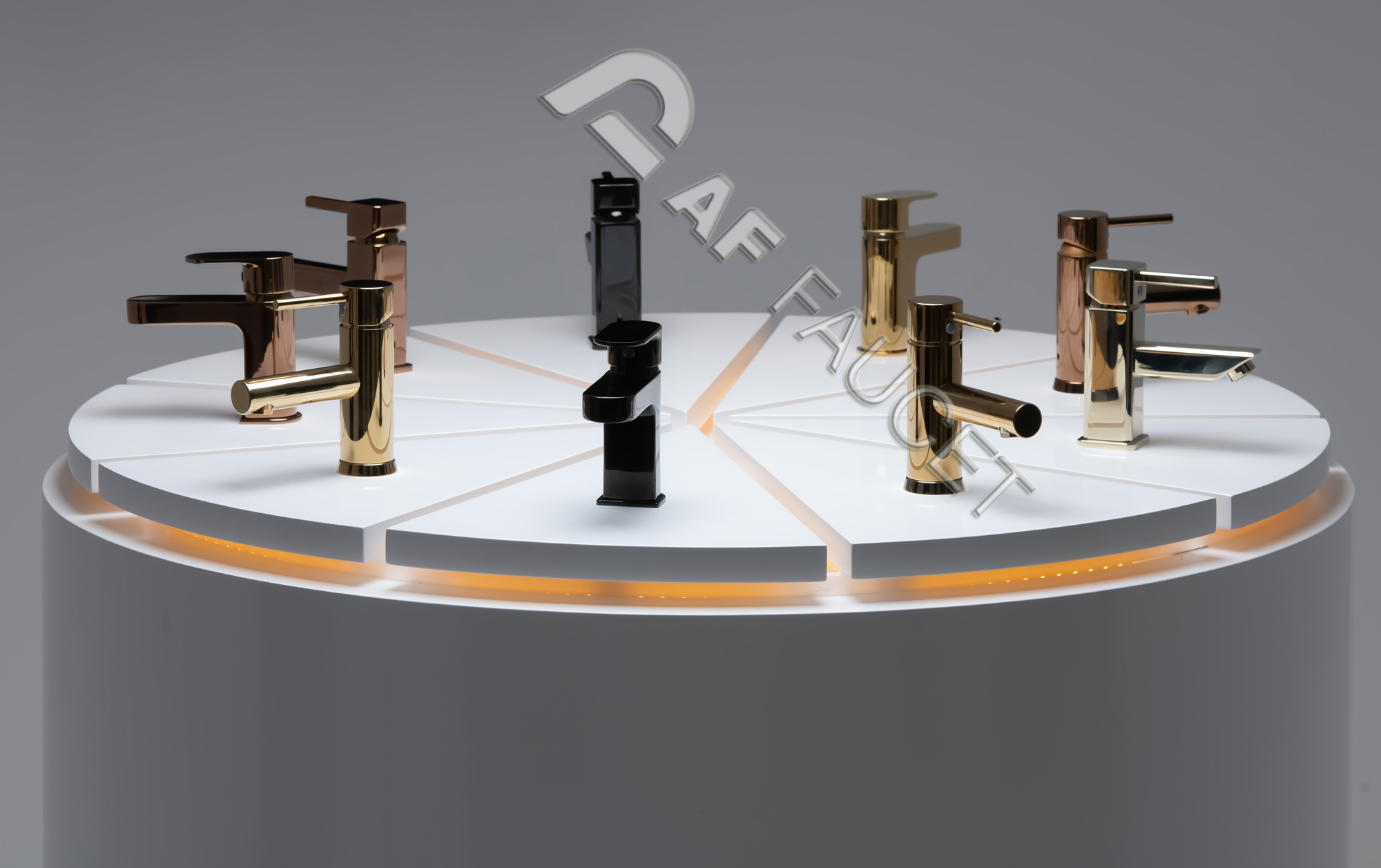

Full Line Faucet Manufacturing Machine - molds design, casting, CNC

machining, grinding and polishing, PVD coating

Turnkey Solutions:

Investment Project

Whole Plant Design

Market Consultation

Machinery

Technician Training

Know-How to Transfer The Technology

The faucet's main production procedures include casting, mechanical

processing, surface treatment, assembly and testing etc. .

1. Casting process

a. Product design

b. Mold design and manufacturing

c. Mold's repair and maintenance

d. Sand mixing/mixer

e. Sand Core blower

f. Low-pressure die casting machine/heavy casting

g. Sand cleaner

h. Sawing machine

The most important production procedure is casting. The sand core's

quality plays an important role in this production process, as it

forms water channels in the faucet body during casting. A solid

core is made from fine sand and a hardening agent by heating in a

core box.

The core is made from fine sand and it forms the waterways for the

faucet body during the casting

sand core's production

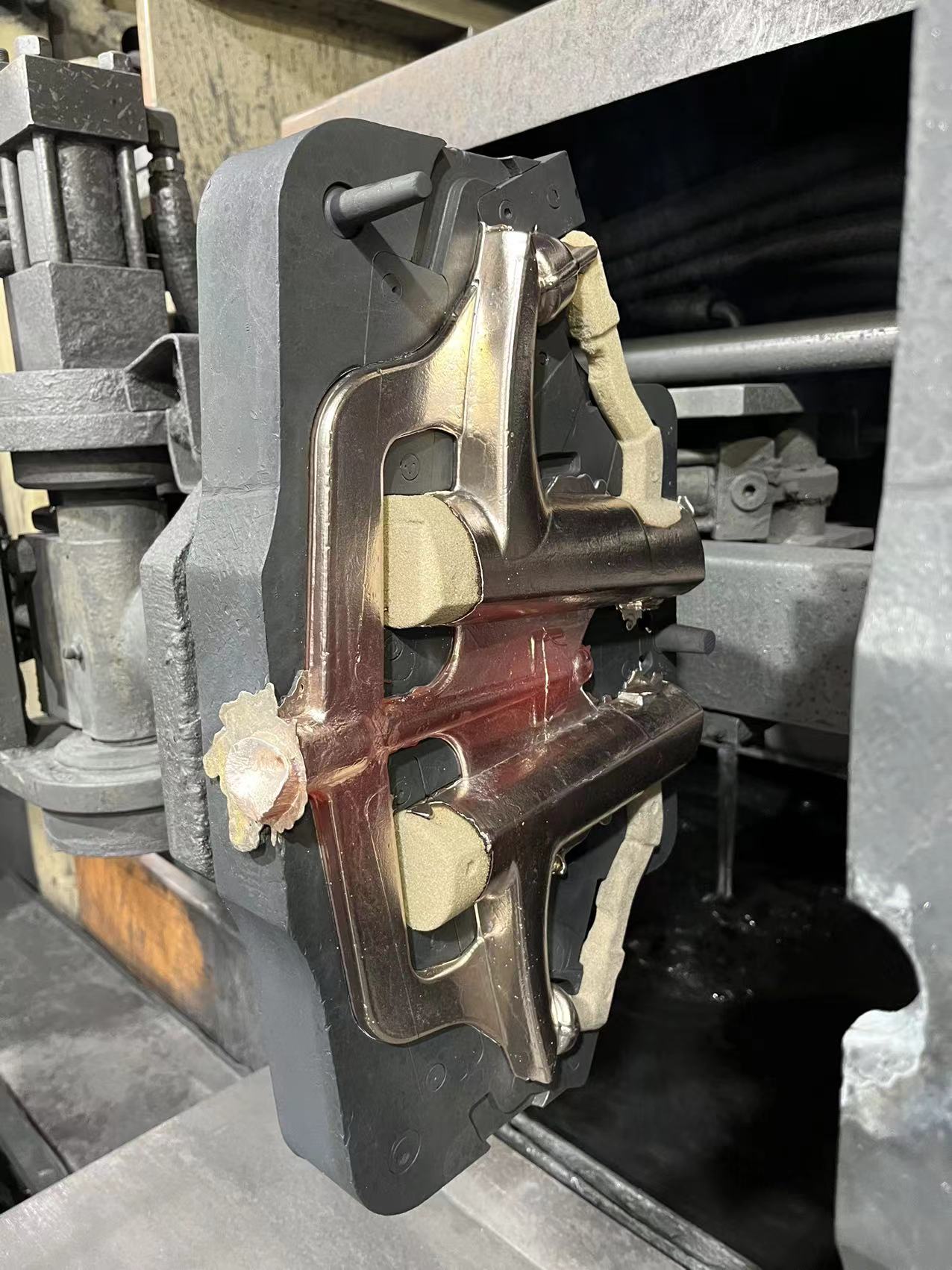

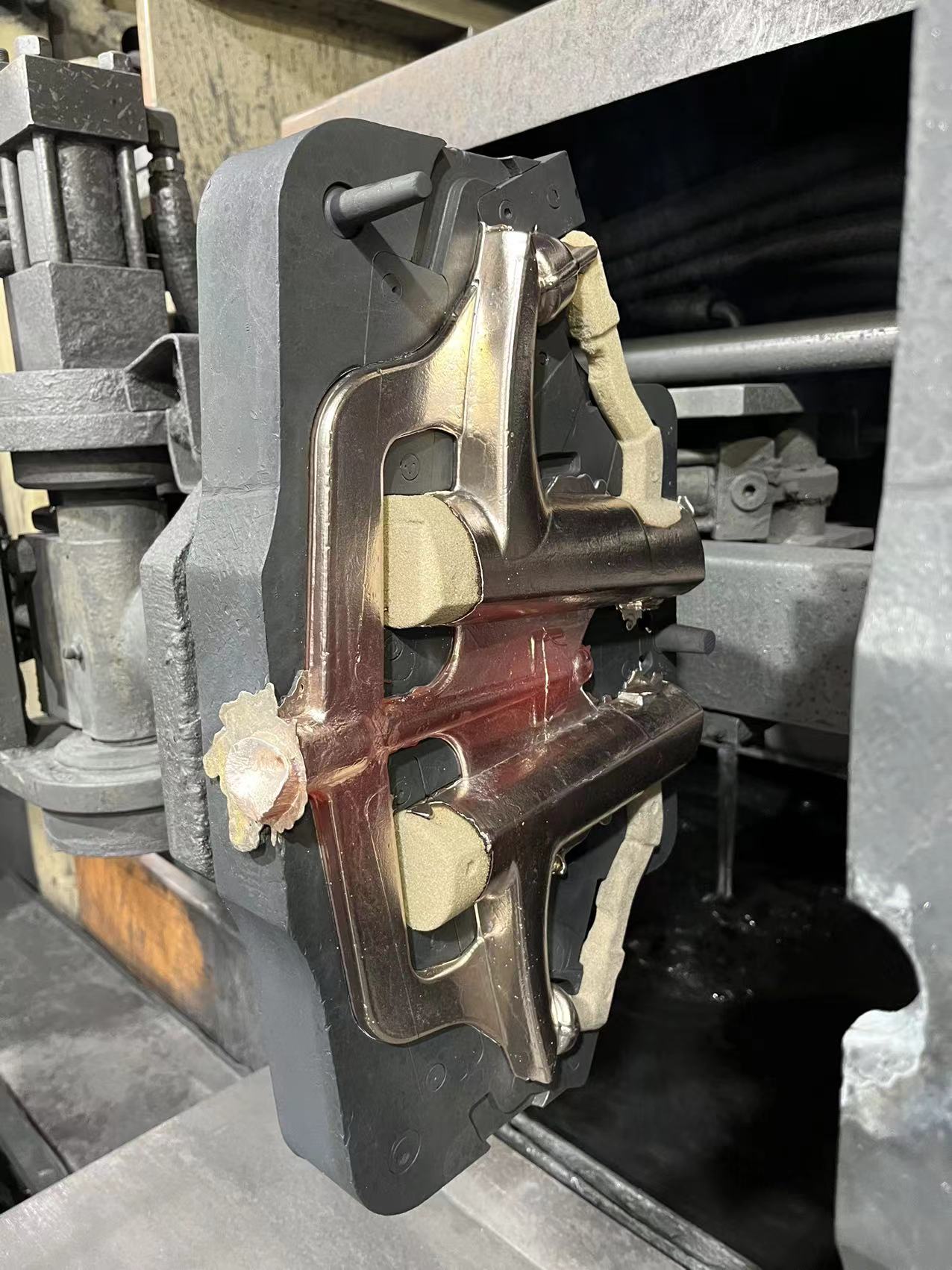

During casting, the shell mold is dipped into a water and graphite

bath. The operator places the cores inside the mold and removes any

loose sand from the shell mold using compressed air.

The cores are placed inside the mold.

The mold is sealed and placed in the blazing-hot casting chamber of

the casting furnace. Three tons of molten brass flow from the

casting furnace into shell molds. The core maintains waterways open

inside the mold, to which technical components are installed and

through which water flows through the faucet.

Molten brass flows into the shell molds.

After cooling down, the caster uses tongs to move the cast to cool

down. Next, the core is removed from inside the faucet body by

whirling it in a mill equipped with metal balls.

LPDC casting steps

Cooled faucet bodies delivered from the foundry are separated from

each other by sawing, and any parts that were necessary during

casting but not included in complete faucets are removed.

2. Machining

Get the brass casting after annealing, using a CNC

numerically-controlled machine tool and another machine tool to

process the brass casting,to make it dimensional, accurate, and

position meet drawing requirements.

Proceed to polish, take outrags, rough surface, and potholes on the

surface, and make the product surface have no obvious sand holes

and hole defects after completion of machining. Grinding polishing

processing, after polishing, use the high-speed rotating wheel to

grind workpiece surfaces, make it smooth and bright, and increase

the brightness of the product surface.

3. Surface treatment.

Matte and Bright Chrome electroplating line, PVD (Physical Vapor

Deposition) vacuum coating processes.

4. Accessories process

The shaft, screw nut, screw, etc., which are used for faucets, need

to forge and press from the copper bar into copper pieces, and then

Processed thread according to the need by the machining technician,

commonly known as tapping.

5. Assembly

After faucet castings pass the test after plating, then into the

assembly process. Assembly is the processing that content faucet

components according to certain order and technology, become a

complete set of faucet products, and realize the function of the

product design process reliably.

6. Testing

Please contact us to assist you build the production line and

improve the quality for each manufacturing procedure.